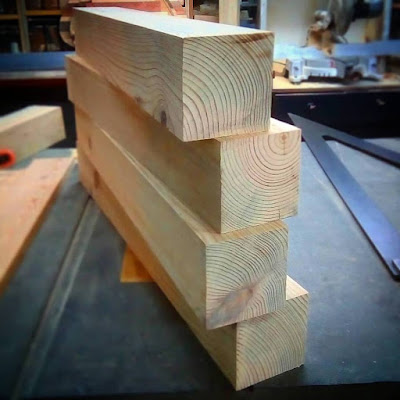

We just started a new project. Making a Farmhouse Table that will be 250 cm long and 100 cm wide. It will be resting on "A" frame legs. That means sawing the 9x9 cm legs to length in a 6.5-degree angle. Our mitre saw doesn't allow such thick material so... old-fashioned muscle power.

The first 8 cuts didn't take that long but still turned out enough work to have a break and make sure everything is cut right, calculations are accurate and the joints, visualized in my head, are "makeable".

A fresh start on the construction today!

NOT JUST SAWDUST

Não Só Serradura - Woodworking and Recycling

2018-06-08

A very late update, finished projects and future adventures

It's been a while since we put an update on our blog. It's a shame, yes it is.

With all the new social media opportunities to share news and work, the blog get's easily forgotten. Instagram, Facebook, Pinterest, Lumberjocks, all easy and quick media to share short messages and pictures. Nevertheless, we're going to try to take this more seriously. It's not that easy to "streamline" all posts in different media and we're looking to construct some kind of schedule which should make things go more smoothly. Here's a list of "social media" links regarding our recycling and woodworking:

With all the new social media opportunities to share news and work, the blog get's easily forgotten. Instagram, Facebook, Pinterest, Lumberjocks, all easy and quick media to share short messages and pictures. Nevertheless, we're going to try to take this more seriously. It's not that easy to "streamline" all posts in different media and we're looking to construct some kind of schedule which should make things go more smoothly. Here's a list of "social media" links regarding our recycling and woodworking:

Finished woodworking projects are shared on:

If you are interested in "behind the scenes" updates and exclusive footage there is the possibility to support us on Patreon!

Of course, our main channel of sharing the projects we're working on is YouTube.

From now on we hope to keep this blog up to date and share whatever news there is from the Not Just Sawdust workshop!

2017-12-28

Bathroom wall cabinet animation.

As of 2018 we are going to try to make a short video of every item. This is the first attempt.

This animation belongs to video #94

2017-12-16

2000 Youtube Subscriber Give-Away

Yes, we reached over 2000 Subscribers on Youtube! Let's keep the tradition going by having a Give-Away. As there are certain deadlines to concur before X-mas, we combined this event with one of our December month items! A big thank you to all subscribers!

To be on the list of potential winners of one of the analogue emergency lights you just comment below! Of course, you need to be a subscriber to the Not Just Sawdust Channel, but if you are not, here's your chance to do so! The winners will be drawn in the first video of 2018. It's not necessary for participating this Give-Away, but it will be much appreciated if you share a link to this video (or one of your favourites on our channel)

To be on the list of potential winners of one of the analogue emergency lights you just comment below! Of course, you need to be a subscriber to the Not Just Sawdust Channel, but if you are not, here's your chance to do so! The winners will be drawn in the first video of 2018. It's not necessary for participating this Give-Away, but it will be much appreciated if you share a link to this video (or one of your favourites on our channel)

2017-11-29

Repairing an old wooden stepladder

Good old quality craftsmanship. Sometimes you just don't realize that you are relying on the skills of a woodworker / carpenter / maker from decades ago. When you used an old stepladder happily for years it doesn't come to mind that at some day even the product of decent carpentry will break down. The good thing about older tools and furniture (called vintage nowadays), is that it is absolutely rewarding to repair them. (unlike the plastic mass produced stuff) This is an example of just a simple old wooden stepladder.

After years of carrying heavy loads, folding up thousands of times. this little stepladder's steel rod widened the hole were it was pivoting in. In the end it came out. A simple repair that could be done different ways.

The first idea was to take of the steel rod and replace it with a longer threaded rod, drilled thru the sides and kept in place with 2 nuts on the outside. Yes, it would have made it very sturdy, but it would also change the looks.

The second option was to just fill make the hole bigger, fill it with a wooden plug and drill the same 13mm hole again at the same spot. The trouble however in the first place was probably the just 1 cm dept of the hole.

So I decided to go for the third option, putting to little external blocks on the inside of the stepladder's legs. To protect the wood I felt it would be a good option to put a few copper pieces of pipe inside the wood so the steel bar would pivot in those.

After years of carrying heavy loads, folding up thousands of times. this little stepladder's steel rod widened the hole were it was pivoting in. In the end it came out. A simple repair that could be done different ways.

The first idea was to take of the steel rod and replace it with a longer threaded rod, drilled thru the sides and kept in place with 2 nuts on the outside. Yes, it would have made it very sturdy, but it would also change the looks.

The second option was to just fill make the hole bigger, fill it with a wooden plug and drill the same 13mm hole again at the same spot. The trouble however in the first place was probably the just 1 cm dept of the hole.

So I decided to go for the third option, putting to little external blocks on the inside of the stepladder's legs. To protect the wood I felt it would be a good option to put a few copper pieces of pipe inside the wood so the steel bar would pivot in those.

It turned out a good solution. The rod goes 2 cm deeper in to the holes on both sides which makes it a sturdy connection.

After a coat of paint this repair won't have changed much to the looks, and this little stepladder will be a safe device for many years to come, for instance to put the Christmas decorations up!

2017-11-02

Repairing an old chair.. the friendly way.

Just a wobbly old chair, well maybe not just. There was a crack that went thru to one of the back legs with all consequences of... falling apart. It was just a matter of a little brace, some dowels and some glue... Here's the process of repairing an antique chair without making it look like a new one.

The crack in the seat at one of the rear legs

Taking all apart without damaging the parts. |

Chiseling out the place for the bracket (mahogany)

glueing in, drilling holes and some reinforcement with dowels

planing the bracket but leaving it just a millimeter proud of the surface, a repair to an antique chair should look like it's been done sometime ago

The back was lose to, 2 10mm beech dowels were hammered in all the way thru the tenons of the back

The three insite thinner parts of the back got the same treatment, only with 8mm dowels

the legs were cut 1 mm shorter, so the fitting became tighter. It's great to find that a little Japanese pull saw is capable to cut slices of 1 mm.

You can't use to much glue if there's room for it to squeeze out of the joint.

The oak legs were put back into the cherry wood seat

It's up to the owner of the chair whether to leave the repair visible or not.

After the glue dried.. a sturdy little antique chair.

2017-10-20

Not just a library project

Part of the materials were already on side, although the idea of changing the original plans (without a backside) made it necessary to recut most of the wood. It is going to be an "all around the room" project.

All profiles are routed at the workshop. Yes there is "readymade" material available in different DIW shops but first of all in Portugal that's sold for ridiculous prizes and secondly, it will never fit custom made sizes. As this all is installed in a historic property, not one wall is straight, nor are floors and ceilings. It makes it more difficult but at the same time requires a feel for style and an eye for "simple details that fit the building.

Two walls are done... time for finishing touches...

2017-08-24

Eight weeks away from home (part 3)

A week of almost a real holiday!

After the birthday party on the first of July we headed towards family around Almere, spend a day and a night and drove the next day to Haarlem where we unloaded the big BMW motorbike and, yes, loaded up an old moped for transport to Portugal

Although we wanted to meet some friends in Amsterdam and Bergen aan Zee, because of the one week delay, it turned out to be more wisely to drive from Haarlem straight to Den Helder where we would take the ferry to Texel, to visit family members who are living on the island.

At arrival we build a new bed in the van so we had our own place to sleep again. The nice weather, the see, the beach and the numerous moments of coffee or other liquid treatments on terraces, gave us a real feeling of being actually on a holiday. Sadly it could not last that long, and a few days later we would take the ferry, accompanied by a little niece that had a hard time letting go of our four legged Ella, back to the mainland and drive over the “Afsluitdijk” towards the North-East of the Netherlands.

Although The Netherlands are a small country, the distance between the western coast and the eastern border takes half a day when you are driving an old van like we do. It’s an enjoyable landscape though and having a dog traveling with you makes it necessary to stop at least every two hours. Time had come to meet old friends in Ter Apel.

Next time: a few days filled with old habbits...

Subscribe to:

Posts (Atom)